Manufacturing Process of Poly bags

Manufacturing of Poly bags

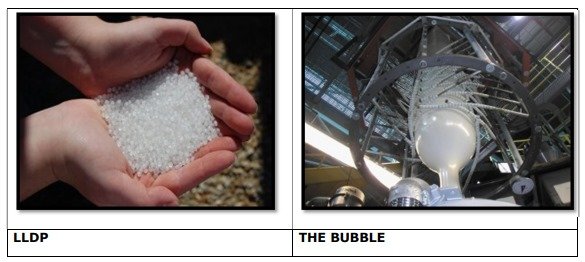

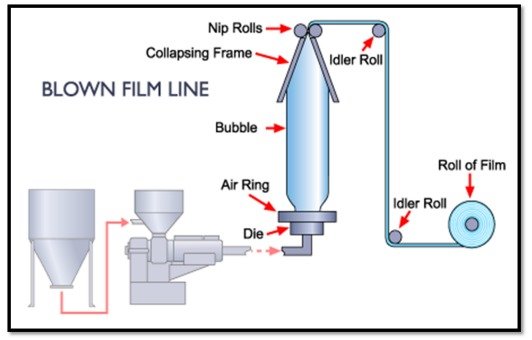

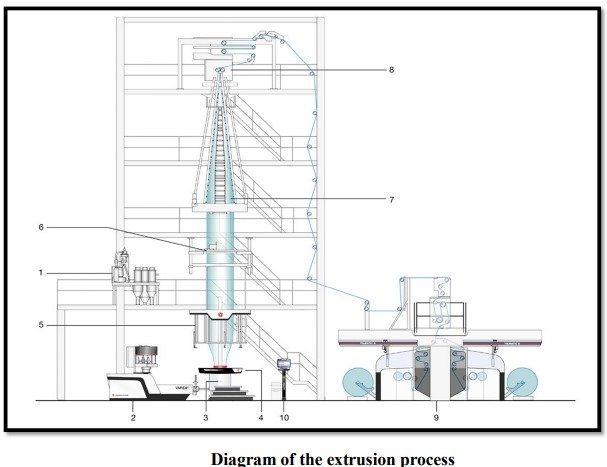

The process for making polyethylene film and bags is called extrusion. This plastic film manufacturing process starts with melting down small plastic pellets, (called resin), until they become molten and pliable.The molten plastic resin (LLDPE) is pushed, (extruded), through a circular die to form a continuous tube of plastic called the bubble. The bubble is inflated with air to the desired diameter and drawn vertically up a tower giving it time to cool before it is flattened to its lay-flat width. The thickness of the film is controlled by the speed at which it is pulled from the die. The width of the film is controlled by the amount of air inserted in the bubble. Film color can be changed in the molten process by adding resin pellets that contain colored pigment. Many things can be done during this “inline” process. A printing press may be printing images, instructions, warnings, company logos, etc. on the film. A bag making machine can seal and perforate the film to form varying lengths of bags on rolls. The film can be cut and separated for individually cut bags. You can also add vent holes, which are punched through the film in a variety of patterns and sizes.The inline plastic film manufacturing process has some further processing limitations. If the film requires more technical alterations then rolled film will be taken off the extrusion line to be further modified in what is known as out of line converting. At this stage, Process printing and laminating, in addition to the plastic bag manufacturing process of making side weld bags, reclosable bags, and wicketed bags is done out of line.

STEP 01 :

The Blown-Film Extrusion Process

The first step of making poly bags is the blown-film extrusion process. The following occurs when using this process: Small plastic pellets (called resin) are first melted down under controlled conditions, until they become molten and pliable. Once resin pellets reach the desired level of pliability, they are then pressed (extruded) through a circular die gap to form a continuous tube of plastic. In this molten state, the tube of plastic is pinched off at one end, and then inflated and stretched to the size and thickness of the desired finished product. The inflated bubble of plastic is drawn vertically up a tower so that it has a chance to cool before it is flattened out and wound onto a roll. Once the plastic is on a roll, it can be cut to form tubing, single-wound sheeting, or center fold sheeting. Most often, we transform the plastic into polybags.

STEP 02:

Making Poly Bags from Plastic Rolls

After the blown-film extrusion process is complete, we take those rolls of plastic and transform them into poly bags by doing the following:

- Rolls of plastic tubing or sheeting are first fed through a machine that draws the material out to the proper length

- The machine then places a seal on the material at the correct length and cuts it off to make an individual bag.

- This process is then repeated until we have the number of poly bags we need for an order.

STEP 3 :

Printing on Plastic Bags

Most single-use plastic bags consist almost entirely of pure polyethylene molecules. However, the plastic bags you get at most shopping malls and supermarkets usually have some sort of color print on them.The process of printing on super sensitive/light material such as plastic bags is called flexographic printing. Depending on the dyes that are used, color printing on plastic bags can be toxic.This in itself poses health risks to marine animals once the plastic bag lands up in the ocean, which they eventually always do.

STEP 04:

Completing the Manufacturing Process

Finally, the two printed sheets are then pressed together at the edges, effectively sealing the bag.The sealed plastic bag can then be cut to desired sizes, depending on the commercial intent for the bag.At this stage in the process, manufacturers can implement custom designs on the bag. For example, they can add a section for easy tearing (like the plastic bags you find at the fruit and vegetable section of the grocery store).